Table of contents

Electromgnatic inspection system

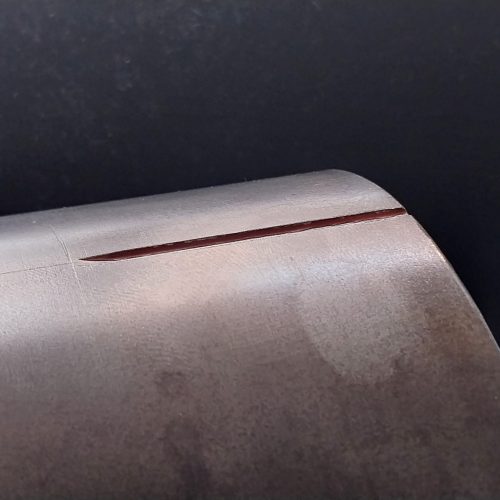

To reach the black gold, drilling pipes have to penetrate deep into the earth. For medium-deep drilling of around 2000 m in depth, approximately 222 pipes of 9 m each are required. A new pipe has to be screwed on every 9 m.The material has to withstand a lot and be durable. Faultless material that meets international standards is thus essential. For this purpose one of the equipment that Used to check the condition of pipes in the drilling industry Is the EMI system. Which is actually the most accurate method to detect possible defects.